Menon’s 100,000 t/year corn protein refining project has obtained a Shandong feed production licence after completing key safety, fire, completion, and environmental permits. The company says its enzyme-hydrolysed corn protein can help ease China’s feed-protein shortage, though research notes remaining issues around stability, quality control, and cost.

Menon said its “100,000 t/year corn protein refining project” has cleared a string of key compliance milestones and has now obtained a feed production licence, a step that moves the plant closer to full commercial operation and has now obtained a feed production licence.

The company said the project has completed fire safety acceptance, the “three simultaneities” safety acceptance (design, construction, and commissioning), and final completion acceptance, and has also received its pollutant discharge permit. The implementing subsidiary recently received the Feed Production Licence issued by the Shandong Provincial Department of Animal Husbandry and Veterinary Medicine.

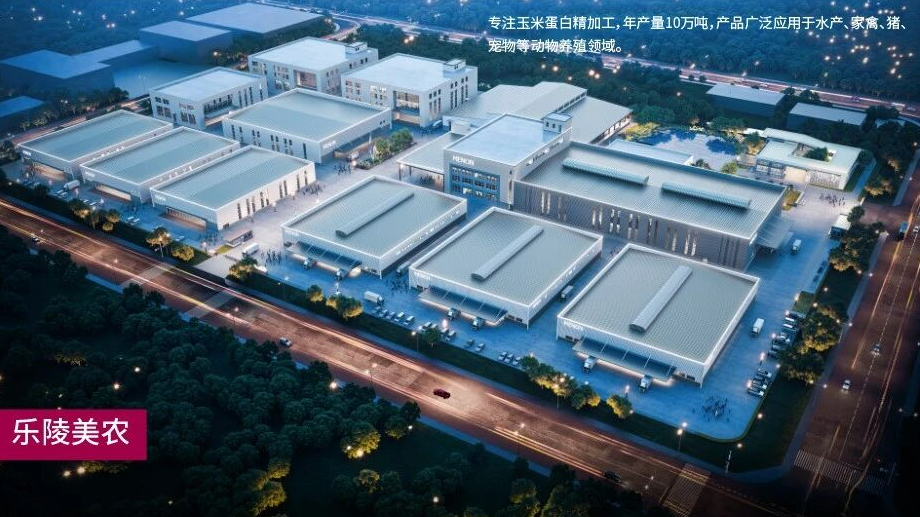

According to the company, the facility was built and invested in by its wholly owned subsidiary Menon Biotechnology (Leling) Co., Ltd. Planned investment is about CNY 391 million (USD 54.46 million).

Menon framed the project against a wider supply challenge. China faces a serious shortfall in feed protein resources, it said, while key protein raw materials remain heavily dependent on imports—citing soybeans and fishmeal, where more than 80% of both are imported.

The company’s corn protein refining product line uses a co-product from corn starch production as the starting material. The process includes enzymatic hydrolysis, concentration, and drying to produce the final product. Menon described this as an industrialised application of bio-enzymatic technology that enables more efficient conversion and utilisation of protein resources, and as a form of synthetic-biology industrialisation that broadens the range of protein products available to the feed sector.

Compared with conventional corn protein feeds, the company said its corn enzyme-hydrolysed protein can significantly improve the availability of protein and energy in corn protein, lifting its nutritional value. In its view, this could help ease tight domestic feed protein supply and aligns with national industrial policy.

A report published by Shi Baoming’s research team at the College of Animal Science and Technology, Northeast Agricultural University, in the 2025 Issue 09 of Feed Industry noted that corn protein powder is an important co-product of corn deep processing. The report said its protein content is higher than soybean meal, giving it potential to replace soybean meal as a high-quality protein resource in feed.

However, the same report noted that corn protein powder has historically underperformed in animal production due to low protein solubility, an imbalanced amino acid profile, and poorer palatability. It added that fermentation and enzymatic hydrolysis technologies can improve protein quality and bioactivity, supporting better feeding outcomes in animal production.

The report also cautioned that challenges remain, including unstable fermentation results, weaker quality control, and cost constraints. How to expand the application of fermented and enzyme-hydrolysed corn protein powder in livestock production, it said, still requires further exploration.

AgriPost.CN – Your Second Brain in China’s Agri-food Industry, Empowering Global Collaborations in the Animal Protein Sector.