Louis Dreyfus Company (LDC) has opened its first commercial specialty feed protein line in Tianjin, China, to produce fermented soybean meal. The 11,000 m² facility, launched on November 2, 2025, has 60,000 t/year capacity and uses co-fermentation to upgrade soybean meal. China’s national fermented soybean meal standard took effect on October 1, 2024.

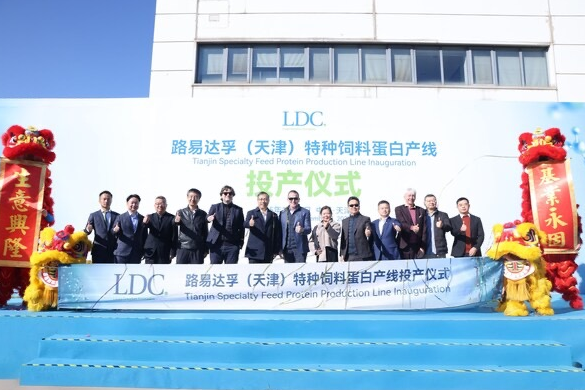

Louis Dreyfus Company (LDC), one of the world’s four largest agricultural merchants, has launched its first commercial-scale specialty feed protein line. The facility in Tianjin, China, held a start-up ceremony on November 2, 2025. Covering 11,000 m², the line will primarily produce fermented soybean meal with an annual capacity of 60,000 tonnes.

“This new line marks LDC’s first commercial production of specialty feed proteins and underscores our continued commitment to the Chinese market,” said Zhou Xuejun, Global President, Plant-based Ingredients Platform; Global Chief Commercial Officer; and President, Asia-Pacific, Louis Dreyfus Company. Zhou added that the plant will supply high-quality specialty feed proteins for China’s livestock and poultry sectors, supporting animal health and production efficiency, while advancing LDC’s plant-based ingredients business.

Co-fermentation to unlock soy value

Developed by LDC’s Global R&D Center in Shanghai, the production system applies a proprietary co-fermentation process. Multiple probiotic strains break down anti-nutritional factors in soybean meal, boosting protein content, palatability, and digestibility. The unit was designed with room to expand into additional specialty feed ingredients covering more farming scenarios and plant sources.

China’s fermented soybean meal momentum—and new national standard

Fermented soybean mealin China emerged from industry-driven innovation that blends traditional solid-state with liquid fermentation for rapid processing. After fermentation, crude protein, phosphorus, crude fat, and amino acid content or utilization increase, while crude fiber declines; beneficial probiotics and bioactive small peptides are also generated.

China’s National Animal Husbandry Station has noted fermented soybean meal as the fastest-growing feed raw material over the past 20 years and a distinctly “China-characteristic” new product. The agency highlights that fermented soybean meal ’s nutritional advantages align with the livestock sector’s transformation and upgrading, warranting further attention to tap its potential, address gaps, and “trade quantity for quality.”

Given fermented soybean meal ’s technical complexity, rapid development, and broad impact, stronger safety oversight is a priority. On October 1, 2024, a national standard for fermented soybean meal—drafted by the Feed Research Institute of the Chinese Academy of Agricultural Sciences and Hubei Bangzhide Animal Husbandry Technology Co., Ltd.—came into force. The standard defines technical requirements, sampling, testing rules, labeling, packaging, transport, storage, and shelf life.

“By improving the quality and efficiency of soybean meal, fermented soybean meal supports soybean-meal-reduction strategies and strengthens the foundation for ‘antibiotic-free’ feed from the source,” the standard’s drafting explanation states.

AgriPost.CN – Your Second Brain in China’s Agri-food Industry, Empowering Global Collaborations in the Animal Protein Sector.