Shanxi-based Changrong Agricultural Technology, led by Jun Yao, has developed an innovative pig production model integrating genetics, nutrition, biosecurity, and digital management. In partnership with global player Cargill, the company supports family farms and mid-sized operations through its patented value chain model. Recent initiatives like the “Sequoia Project” and the “Million Pigs Project” aim to scale production, enhance efficiency, and build resilience against industry risks such as ASF. Changrong’s strategy hinges on data-driven management, premium genetics (Hypor), and precision nutrition, positioning it as a forward-thinking player in China’s evolving pig industry.

After more than two decades in international trade, Jun Yao made a decisive shift in 2014. The chairman of Shanxi Changrong Agricultural Technology Co. left the global trading floor behind to fully embrace a venture he had tentatively begun five years earlier: pig farming. That transition proved more than a career change—it was the start of a strategic overhaul in how small and mid-sized farms in China could raise pigs sustainably and efficiently.

Leveraging his international perspective, Jun Yao steered clear of conventional paths. Instead, he forged partnerships with global agribusiness leaders like Cargill to explore innovative production models. By 2016, Changrong had secured a national patent for its “New Family Farm Model,” which integrates genetics, nutrition, farm design, biosecurity, and digital farm management into a single value chain framework.

Jun Yao

Building from the Foundation

This model starts with site selection and design. From there, Changrong works hand-in-hand with its partners—mostly smallholder family farms with fewer than 500 sows—to establish full biosecurity protocols. The company provides premium genetics and nutrition, deploys digital farm management tools, and offers continuous staff training to ensure consistent performance.

Changrong 120-sow family farm in operation

“Changrong’s model starts at the root,” Mr.Yao says. “It’s about establishing sound fundamentals and delivering systemic solutions.”

Family farms, with their high flexibility and personal commitment, can be highly effective. However, they often struggle with standardization and efficient resource allocation. That’s where Changrong’s integrated support system adds value—by bridging those gaps and boosting operational performance.

Since its founding in 2009, Changrong has invested in several breeding farms. It has worked with various genetic lines, from PIC to Canadian strains, before eventually entering a strategic agreement in 2019 with Hypor (a Hendrix Genetics brand). This partnership introduced synchronized genetic development in China, culminating in a 2,400-head nucleus farm by 2021.

Changrong’s feed, meanwhile, has been consistently sourced from Cargill. With demand growing, the company is now constructing a 300,000-tonne feed mill in Shanxi. The first 150,000-tonne phase is expected to be operational within the year—and will be operated entirely by Cargill.

“In our view, professionals should do professional things,” says Jun Yao.

Innovation Through Collaboration

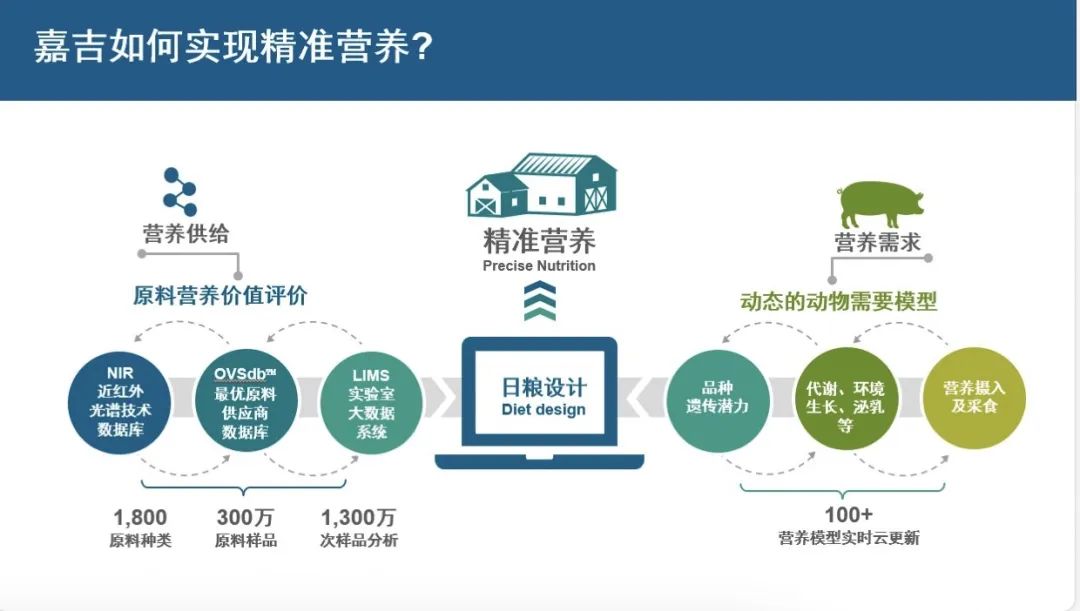

In August 2022, that collaboration took a leap forward. Cargill opened its sixth global and first Asian GIC (Global Innovation Center) , right on Changrong’s breeding base in Shanxi. The GIC focuses on precision nutrition, raw material optimization, smart farming strategies, and sustainable ingredient development—tailored to Chinese and Asian customers.

Cargill Global Innovation Center (GIC) located in Yuncheng, Shanxi Province, China

“Launching GIC is a milestone,” says Quan Taiyong, General Manager of Cargill’s swine feed business in China. “It strengthens both our innovation capabilities and service delivery across Asia.”

To date, Changrong has established partnerships with more than 80 family farms across Shanxi, Shaanxi, Hebei, Inner Mongolia, and Jiangsu—amounting to roughly 70,000 sows in total. The majority—around 30,000—are located in the company’s home region of Yuncheng, forming the core of its value chain ecosystem.

The Sequoia Project: Scaling with Resilience

As some family farms mature, many are seeking to scale up. Meanwhile, mid-sized farms with over 1,000 sows face increasing risks, particularly in regions still impacted by African Swine Fever (ASF). In response, Changrong has launched the “Sequoia Project.”

“The Sequoia Project—named after the redwood tree, known for its interconnected root system and storm resilience—aims to build a horizontally connected supply chain with unified genetics, nutrition, management systems, and risk-sharing mechanisms.” Mr.Yao explains,“Redwoods are among the tallest in the world—but their roots are deeply interconnected, allowing them to withstand even the fiercest storms. That’s the model we want for the swine industry.”

Inspired by cooperative models in Europe and vertically integrated groups in China, Sequoia aims to build a horizontally connected supply chain—one with unified genetics, nutrition, management systems, and risk-sharing mechanisms.

Under this model, if a participating farm experiences stock loss, Changrong will replenish pigs at cost. Standardized benchmarks and shared data systems will underpin operations. The target: weaning cost at CNY 280 per piglet and a finishing cost (7–120 kg) of CNY 11 per kg.

A key enabler of this model is Cargill’s data analytics and farm management platform, which allows real-time performance tracking across all farms in the alliance.

“Everyone in the Sequoia Project will operate under one data system,” Mr.Yao notes. “The same genetics, nutrition, and management allow us to truly drive performance, reduce costs, and weather challenges together.”

Taiyong Quan adds, “Good genetics, good nutrition, and good management are the three essential pillars. Digitalization is what makes consistent excellence possible.”

Taiyong Quan

Cargill has also initiated a bold “36–5 Challenge” across China—targeting 36 pigs per sow per year (PSY) and a comprehensive cost below CNY 10 per kg. Through specialized nutrition, health programs, alliances, and training, the company is helping family and mid-sized farms meet this ambitious target.

Strategic Anchor: One Million Pigs

In early 2025, Changrong announced its “Million Pigs Project”—a three-year plan to scale up to 50,000 sows and produce 1 million market pigs annually.

To support this, the company imported nearly 900 Hypor great-grandparent (GGP) pigs from the US at the end of 2023. These have since expanded to around 1,700 heads, with full-capacity production expected by the end of this year.

Changrong is also leveraging Hypor’s 2021 acquisition of Danish Genetics to explore hybrid breeding options that combine robust productivity with China’s market needs.

Currently, its original 2,400-head nucleus farm now serves as a GP multiplication site, while a neighboring farm—home to the Cargill GIC—houses a PS-level herd for applied R&D under commercial farming conditions.

Cargill has already developed a custom nutrition program for Changrong’s Hypor lines. “It’s like a high-end vehicle that needs premium fuel,” Mr.Yao says. “The right nutrition unleashes its full performance potential.”

According to Dr. Wu Yanan, Director of Nutrition and Strategic Accounts at Cargill Animal Nutrition, the collaboration benefits from Cargill’s global ingredient database and Hypor’s breeding expertise—delivering practical gains in both productivity and profitability.

Dr. Wu Yanan

Beyond R&D, Changrong is also opening its facilities for industry visits—positioning the GIC as both a research platform and a brand ambassador.

From Family Farms to Full Integration

Going forward, Changrong will continue to support family farms, particularly in Shanxi province, where it can maintain close ties and optimize service delivery. The company also established a new multiplication base via joint venture in Lvliang, Shanxi, targeting 300,000 head of finisher pigs annually.

Ultimately, the “Million Pigs Project” lays the foundation for future integration with downstream processing. “With more finishing capacity, we aim to connect with slaughterhouses,” Mr.Yao says. “That will give us a fully integrated chain—and greater resilience.”

And with Cargill as a long-term partner, Jun Yao believes they’re just getting started.

AgriPost.CN – Your Second Brain in China’s Agri-food Industry, Empowering Global Collaborations in the Animal Protein Sector.