At the 2025 China Feed Industry Expo, record attendance underscored the feed sector’s rapid pivot toward smart technologies and precision nutrition. Despite market headwinds, companies like Cargill and Danisco showcased digital platforms and enzyme innovations that support feed efficiency, grain reduction, and sustainable livestock production—fully aligned with national policy priorities on resource optimisation.

The 2025 China Feed Industry Expo, held in Qingdao, drew more than 100,000 visitors and spanned over 100,000 square metres of exhibition space—setting a new benchmark in the event’s history. Organised by the China Feed Industry Association, the expo’s scale is particularly striking given the ongoing sluggishness in the country’s feed and livestock markets.

The strong turnout underscores growing anticipation for innovation in feed technology, additive development, and digitalisation—all driven by China’s strategic shift towards what it calls “new quality productive forces” (新质生产力), a policy framework promoting tech-driven agricultural modernization.

Technology leaders showcase smart solutions

Global feed and nutrition leaders seized the opportunity to align with this new trajectory. At Danisco’s booth, company representatives pointed to a 10% growth in their China business during 2024, primarily attributed to enhanced laboratory services. These now include precise analysis of complex feed ingredients—such as corn Proma and RSD60 starch analysis—enabling tailored enzyme applications that improve digestibility and boost feed conversion efficiency.

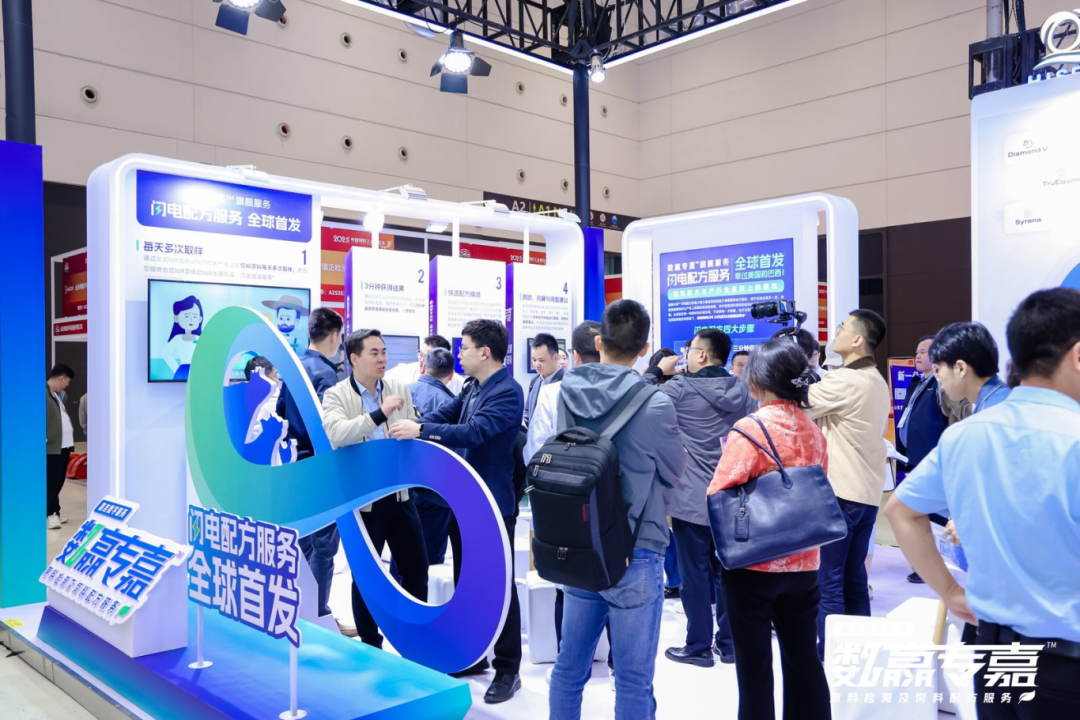

Meanwhile, Cargill introduced its proprietary Agriness “Lightning Formula” to the Chinese market. The four-step system integrates near-infrared spectroscopy (NIR), CNC nutrient analysis, BRILL optimisation, and MAX software to enhance nutrient extraction and consistency across batches. This enables feed adjustments in as little as three minutes while maintaining precise formulation, optimising performance and profitability.

As Zhang Hesheng, former Party Secretary of the Chinese Academy of Agricultural Sciences, aptly summarised: real agricultural productivity gains will stem from revolutionary technologies, smarter resource allocation, and systemic industrial upgrading.

Policy alignment: feed efficiency, less grain, greater sustainability

Policy direction from the Ministry of Agriculture and Rural Affairs (MARA) resonated throughout the expo. In his keynote speech, Wang Zongli, President of the China Feed Industry Association, urged the sector to embrace a “Big Agriculture, Big Food” mindset. He called for the broad implementation of MARA’s feed-saving action plan, with priorities including improved feed conversion ratios (FCR), enhanced resource efficiency, and output maximisation per input unit.

Key measures promoted by the government include:

- Expanding precision feeding and green additive usage,

- Substituting grain-based inputs with agricultural by-products,

- Shifting towards low-grain feedstocks and breeds with lower feed requirements.

Wang Lejun, MARA’s Chief Veterinarian, emphasised that meaningful change depends on tackling two critical barriers: the limited use of non-grain feed resources and insufficient high-quality forage production. He highlighted the role of large feed enterprises in accelerating the adoption of low-protein diets and broader technological implementation.

Given that feed can represent up to 70% of animal production costs, enhancing efficiency and reducing grain use strengthens profitability and supports national food security goals.

Precision nutrition: a smarter way forward

Cargill’s “Spring Action for PSY30+” campaign further illustrates the sector’s shift towards data-driven formulation strategies. One of its key pillars—precision nutrition—is enabled by an expansive data ecosystem:

- Over 1,800 ingredient types,

- 3 million ingredient samples,

- 13 million data points from global analyses.

Using advanced tools such as NIR detection, an Optimal Vendor Selection database (OVSdb), and a LIMS-integrated lab system, Cargill fine-tunes feed to meet the nutritional demands of animals at every stage of growth. Their segmented net energy model, applied especially in pig production, reduces feed waste while improving performance.

At the heart of this system lies MAX—a dynamic formulation engine that balances nutritional accuracy with ingredient value, helping clients reduce FCR by 0.1 units in various production phases. With corn priced at CNY 2,400 per tonne and soybean meal at CNY 3,000 per tonne, each 0.1-point improvement translates into feed cost savings of at least CNY 100 (approximately USD 13.70) per tonne.

AgriPost.CN – Your Second Brain in China’s Agri-food Industry, Empowering Global Collaborations in the Animal Protein Sector.